Electronic design automation (EDA), also referred to as electronic computer-aided design (ECAD), is a category of software tools for designing electronic systems such as integrated circuits and printed circuit boards. The tools work together in a design flow that chip designers use to design and analyze entire semiconductor chips. Since a modern semiconductor chip can have billions of components, EDA tools are essential for their design; this article in particular describes EDA specifically with respect to integrated circuits (ICs).

Electronic Design Automation, or EDA, is a market segment consisting of software, hardware, and services with the collective goal of assisting in the definition, planning, design, implementation, verification, and subsequent manufacturing of semiconductor devices, or chips. Regarding the manufacturing of these devices, the primary providers of this service are semiconductor foundries, or fabs. These highly complex and costly facilities are either owned and operated by large, vertically integrated semiconductor companies or operated as independent, “pure-play” manufacturing service providers. This latter category has become the dominant business model.

How Does EDA ( Electronic Design Automation) Work ?

Electronic Design Automation (EDA) refers to the use of software tools to automate and optimize the design, verification, and manufacturing processes of electronic systems, such as integrated circuits (ICs), printed circuit boards (PCBs), and other hardware components.

Very sophisticated and complex software programs function primarily in one of three ways to assist with the design and manufacture of chips:

- Simulation tools take a description of a proposed circuit and predict its behavior before is it implemented.

- Design tools take a description of a proposed circuit function and assemble the collection of circuit elements that implement that function. This is both a logical process (assemble and connect the circuit elements) and a physical process (create the interconnected geometric shapes that will implement the circuit during manufacturing). These tools are delivered as a combination of fully automated and interactively guided capabilities.

- Verification tools examine either the logical or physical representation of the chip to determine if the resultant design is connected correctly and will deliver the required performance.

Here’s how EDA works:

1. Specification and Design Input

- System Requirements: Define the functionality, performance, and constraints of the electronic system.

- High-Level Design: Engineers create specifications in the form of block diagrams, schematics, or hardware description languages (HDLs) like VHDL or Verilog.

- Capture Tools: Tools like schematic capture software (e.g., OrCAD) are used to input the design.

2. Functional Simulation

- Behavioral Simulation: Simulates the logic and functionality of the design to ensure it behaves as intended.

- Tools: Use simulators like ModelSim or Synopsys VCS to verify logic.

3. Design Synthesis

- HDL to Gate-Level Netlist: The design described in HDL is synthesized into a gate-level netlist using logic synthesis tools (e.g., Synopsys Design Compiler, Cadence Genus).

- Optimization: The synthesis tool optimizes the design for performance, area, and power consumption.

- Constraint Definition: Apply constraints (e.g., timing, area) to guide optimization.

4. Physical Design (For ICs)

- Floorplanning: Arrange the major blocks of the design on the chip.

- Placement: Position standard cells or blocks within the defined floorplan.

- Routing: Connect the placed cells using metal layers for power and signal distribution.

- Timing Closure: Ensure the design meets timing requirements through static timing analysis (STA).

- Tools: Cadence Innovus, Synopsys ICC, or Mentor Calibre are commonly used.

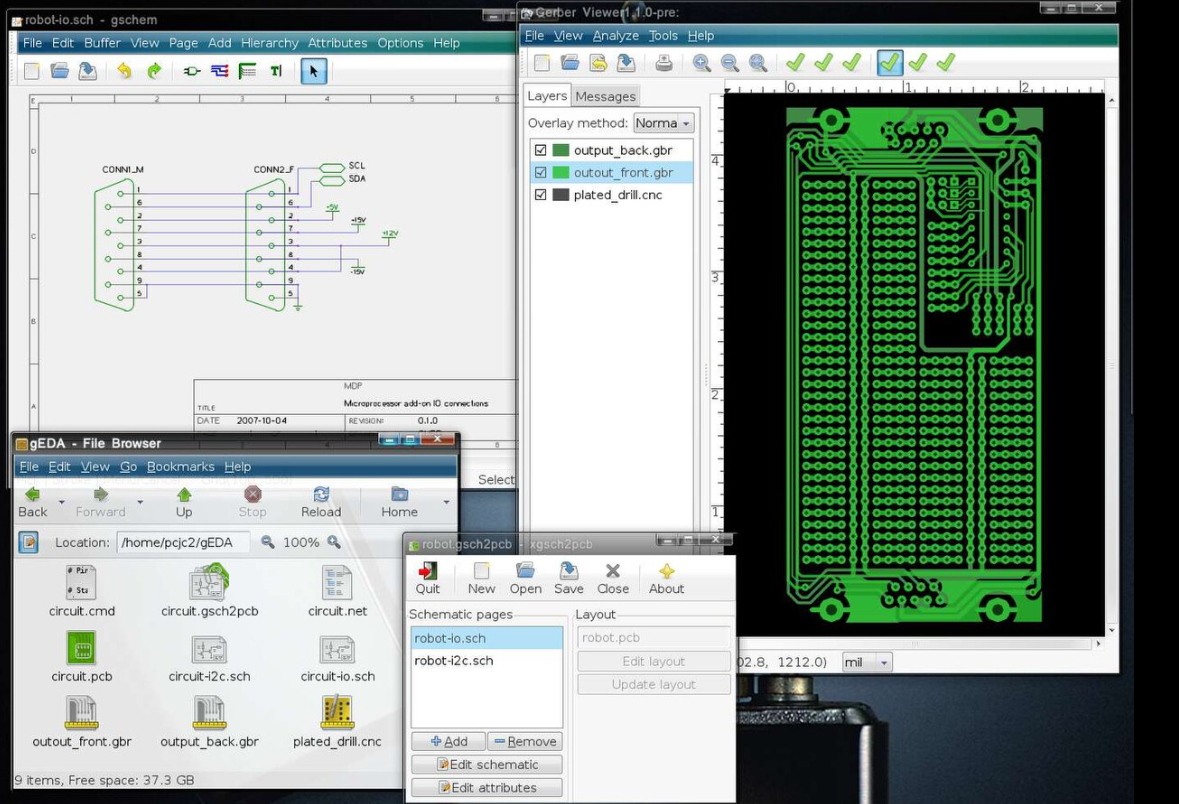

5. PCB Design (For Boards)

- Component Placement: Arrange components on the board for optimal performance.

- Routing: Connect components with traces while adhering to design rules (e.g., signal integrity, impedance).

- Design Rule Checking (DRC): Ensure the layout complies with manufacturing constraints.

- Tools: Use software like Altium Designer, KiCad, or Cadence Allegro.

6. Verification and Validation

- Static Verification: Check for errors such as design rule violations, signal integrity issues, or power integrity problems.

- Functional Verification: Use tools like UVM (Universal Verification Methodology) to ensure the design behaves as expected.

- Physical Verification: Perform Design Rule Checks (DRC), Layout vs. Schematic (LVS) checks, and Electrical Rule Checks (ERC).

7. Design Iteration

- Based on verification results, make necessary corrections to improve functionality, performance, or manufacturability.

8. Manufacturing Preparation

- Generate Files: Create manufacturing files such as Gerber files (for PCBs) or GDSII files (for ICs).

- Design for Manufacturability (DFM): Optimize the design to ensure efficient and error-free production.

- Test Patterns: Generate test patterns for post-fabrication testing.

9. Fabrication and Post-Fabrication Testing

- Fabrication: ICs are manufactured at foundries, and PCBs are fabricated at board houses.

- Testing: The fabricated product undergoes rigorous testing to ensure it meets specifications.

10. Continuous Improvement

- Feedback from testing and production is used to improve future designs.

- The EDA process is iterative, ensuring the design meets all functional, performance, and cost requirements.

Types of EDA Tools

Electronic Design Automation (EDA) tools are categorized based on the specific stages of the electronic design and manufacturing process they support. These tools cater to tasks such as simulation, synthesis, verification, physical design, and more. Below are the major types of EDA tools and examples for each:

1. Schematic Capture Tools

- Purpose: Used to create circuit diagrams or schematics that describe the connectivity of the electronic components.

- Examples:

- OrCAD Capture

- KiCad

- Altium Designer

2. Simulation Tools

- Purpose: Simulate the behavior of a circuit or system at different abstraction levels (e.g., functional, timing, analog).

- Types:

- Logic Simulation: Simulates digital circuits at the logic level.

- Analog Simulation: Simulates continuous-time analog circuits.

- Examples:

- ModelSim (for HDL-based simulation)

- Cadence Spectre (for analog simulation)

- SPICE (Simulation Program with Integrated Circuit Emphasis)

3. Synthesis Tools

- Purpose: Convert high-level designs written in HDLs (e.g., VHDL, Verilog) into a gate-level netlist.

- Examples:

- Synopsys Design Compiler

- Cadence Genus

- Mentor Graphics Precision

4. Layout Design and Physical Design Tools

- Purpose: Create the physical layout of circuits, including placement of components, routing of interconnections, and layer assignments.

- Examples:

- Cadence Innovus

- Synopsys IC Compiler II

- Mentor Graphics Calibre (for verification)

5. Verification Tools

- Purpose: Ensure the design meets functional, timing, and physical constraints.

- Types:

- Functional Verification: Verifies the design logic using simulations or formal verification techniques.

- Static Timing Analysis (STA): Ensures the design meets timing constraints.

- Physical Verification: Checks for errors in the layout (e.g., Design Rule Checks (DRC), Layout vs. Schematic (LVS)).

- Examples:

- Synopsys PrimeTime (for STA)

- Cadence Xcelium (for functional verification)

- Mentor Graphics Calibre (for physical verification)

6. PCB Design Tools

- Purpose: Design printed circuit boards, including component placement, routing, and design rule checking.

- Examples:

- Altium Designer

- KiCad

- Cadence Allegro

- Eagle

7. FPGA Design Tools

- Purpose: Create designs for Field-Programmable Gate Arrays (FPGAs) and simulate/test these designs.

- Examples:

- Xilinx Vivado

- Intel Quartus Prime

- Lattice Diamond

8. Power Analysis and Signal Integrity Tools

- Purpose: Analyze and optimize power consumption and signal integrity in the design.

- Examples:

- Cadence Voltus (power analysis)

- Synopsys PrimePower

- Ansys HFSS (for electromagnetic signal analysis)

9. Electromagnetic Simulation Tools

- Purpose: Simulate electromagnetic fields for antennas, RF circuits, and high-speed designs.

- Examples:

- Ansys HFSS

- CST Studio Suite

- Keysight ADS (Advanced Design System)

10. Embedded System Design Tools

- Purpose: Integrate hardware and software components for embedded systems.

- Examples:

- MATLAB/Simulink

- Keil MDK

- ARM Development Studio

11. Multi-Domain Co-Design Tools

- Purpose: Facilitate co-design of hardware and software, often for system-level designs.

- Examples:

- Cadence Virtuoso (analog/digital mixed-signal co-design)

- Synopsys Platform Architect

12. Manufacturing and Test Tools

- Purpose: Prepare designs for manufacturing and generate test patterns to validate hardware after production.

- Examples:

- Synopsys TestMAX

- Cadence Modus

- Mentor Graphics TestKompress

Summary Table

| Category | Examples |

|---|---|

| Schematic Capture Tools | OrCAD Capture, KiCad, Altium Designer |

| Simulation Tools | ModelSim, SPICE, Cadence Spectre |

| Synthesis Tools | Synopsys Design Compiler, Cadence Genus |

| Layout/Physical Design Tools | Cadence Innovus, Synopsys IC Compiler II |

| Verification Tools | PrimeTime, Xcelium, Calibre |

| PCB Design Tools | Altium Designer, KiCad, Eagle |

| FPGA Design Tools | Xilinx Vivado, Intel Quartus Prime |

| Power/Signal Integrity Tools | Voltus, PrimePower, Ansys HFSS |

| Electromagnetic Simulation | Ansys HFSS, CST Studio Suite |

| Embedded System Design Tools | MATLAB/Simulink, Keil MDK, ARM Dev Studio |

| Manufacturing/Test Tools | TestMAX, Modus, TestKompress |

EDA Company Listing and Their Market Capitalization ?

What is EDA and The EDA Company List

Electronic Design Automation (EDA) is a specialized sector within the technology industry, comprising companies that develop software tools to facilitate the design and verification of electronic systems, such as integrated circuits and printed circuit boards. The EDA market is dominated by a few key players, each with significant market capitalizations.

Here is a list of prominent EDA companies along with their market capitalizations:

| Company | Market Capitalization (USD) | Notes |

|---|---|---|

| Synopsys, Inc. | Approximately $70 billion | Synopsys is a leading provider of EDA tools and semiconductor IP. |

| Cadence Design Systems | Approximately $60 billion | Cadence offers a broad range of EDA solutions and has a strong presence in the semiconductor industry. |

| Siemens EDA (formerly Mentor Graphics) | Part of Siemens AG (Market Cap: Approximately $150 billion) | Siemens EDA provides comprehensive EDA tools and is a subsidiary of Siemens AG. |

| ANSYS, Inc. | Approximately $30 billion | ANSYS specializes in engineering simulation software, including EDA tools for electronic design. |

| Altium Limited | Approximately $5 billion | Altium focuses on PCB design software and has a growing market presence. |

Market capitalizations are approximate and based on data available as of January 2025. For the most current figures, please refer to financial news sources or the companies’ investor relations pages.

These companies play a crucial role in the electronics industry by providing tools that enable the design and development of complex electronic systems. The EDA market has been experiencing significant growth, driven by the increasing complexity of electronic devices and the demand for advanced design tools. According to a report by MarketsandMarkets, the global EDA market was valued at USD 14.5 billion in 2022 and is projected to reach USD 26.2 billion by 2028, registering a CAGR of 9.8% during the forecast period.

It’s important to note that market capitalizations can fluctuate due to various factors, including market conditions, company performance, and economic trends. For the most accurate and up-to-date information, it’s advisable to consult financial news outlets or the investor relations sections of the companies’ official websites